Written by Lindsey DiGangi Vice President- Field Operations

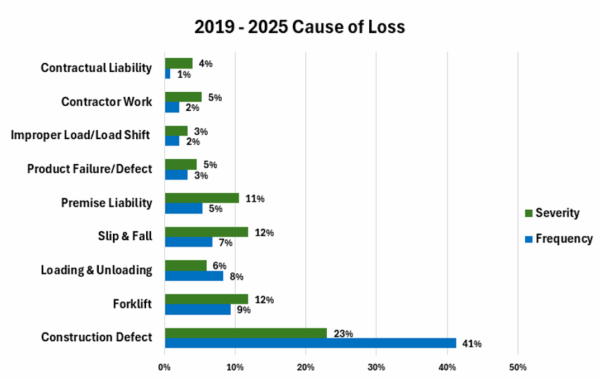

When choosing what to write for our newsletter each edition, we listen, we observe, and we speak from experience. Claims experience, in particular. One area of growing concern is our general liability claims experience. Why is that the case? Simply put, we live in a litigious environment that is constantly evolving. What you do today has the potential to impact your business many years into the future. Here’s a peek into the PLM general liability claims activity over the last 5 years.

The common thread amongst many of our frequent and severe loss types like construction defect, forklift usage, loading and unloading, and slip and fall is that they all come from the normal course of business. How many deliveries to do you make in any given week? Do those start with a forklift in your yard? Do they end with products that will be used in a build? How many deliveries do you receive in a week? Do those include people loading and unloading materials?

We often hear from our insureds “yes, we have a procedure for that”. Having a procedure is a great start, but do you feel confident that each of your employees knows that process, understands why it exists, and executes it consistently? If you can’t answer yes to that statement, then your process is just a hope, and as leaders, you know that hope isn’t a sound business practice.

Let’s break down a few a of these:

- Construction Defect: The most common type of construction defect claim that we see at PLM is one where our insured sells a product that gets installed in a structure and, at some time later, that product fails and a construction defect claim is filed. In many of those instances, someone else- likely a subcontractor, was responsible for the installation of that product. While installation may be a common part of your business, it’s important to remember that the risk associated with it is not benign. That is why we suggest so strongly that you have the proper contractual controls in place with anyone that you might be working with.

- The key elements of those controls include:

- having a clear definition of the scope and responsibilities of their work

- requiring indemnity clauses of the subcontractor

- requiring specific insurance components in your contract, including additional insured status and waiver of subrogation

- requesting warranties of their work standards

- complying with laws and safety standards.

- The key elements of those controls include:

Don’t forget the record keeping! Ensuring all of these elements are in place is only helpful if you can find them.

Read more detail about risk transfer in subcontractor contracts in The Risk Behind Installation | Lumber Memo, Issue 3, 2025

- Forklift: These losses can be some of the most devastating losses to the people they injure. Forklift safety starts at design and continues through to corporate culture. Having designated paths for forklifts can help create consistency that employees and visitors understand. A forklift training program is great for onboarding all new employees, but the training and feedback needs to be continuous to be effective. Are your operators certified? Are those certifications up to date? Make sure your operators are empowered to speak up if something isn’t safe. It can save lives.

To learn more best practices, read out Best Practices for Forklift Safety Article

Loading and Unloading: This is a key area where what we hear and what we see tend to be different. Many businesses have a standard operating procedure for where a driver should be during this process. We hear about them often when our loss control representatives and business development representatives are meeting with insureds. When is the last time you stopped to observe that practice in action? We often make recommendations from observing actions that don’t match written policy. Check out this article we had published in LBM Journal for more about how to prevent losses from loading and unloading: Look Before You Load: Managing Loading and Unloading Risk Amid a Labor Shortage

The mindset of it won’t happen to me isn’t a risk management strategy. Investing in safety early and consistently will not only save you time and money in the long run, it can also save your business reputation.

I welcome any questions at ldigangi@plmins.com or 267-825-9034.